Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

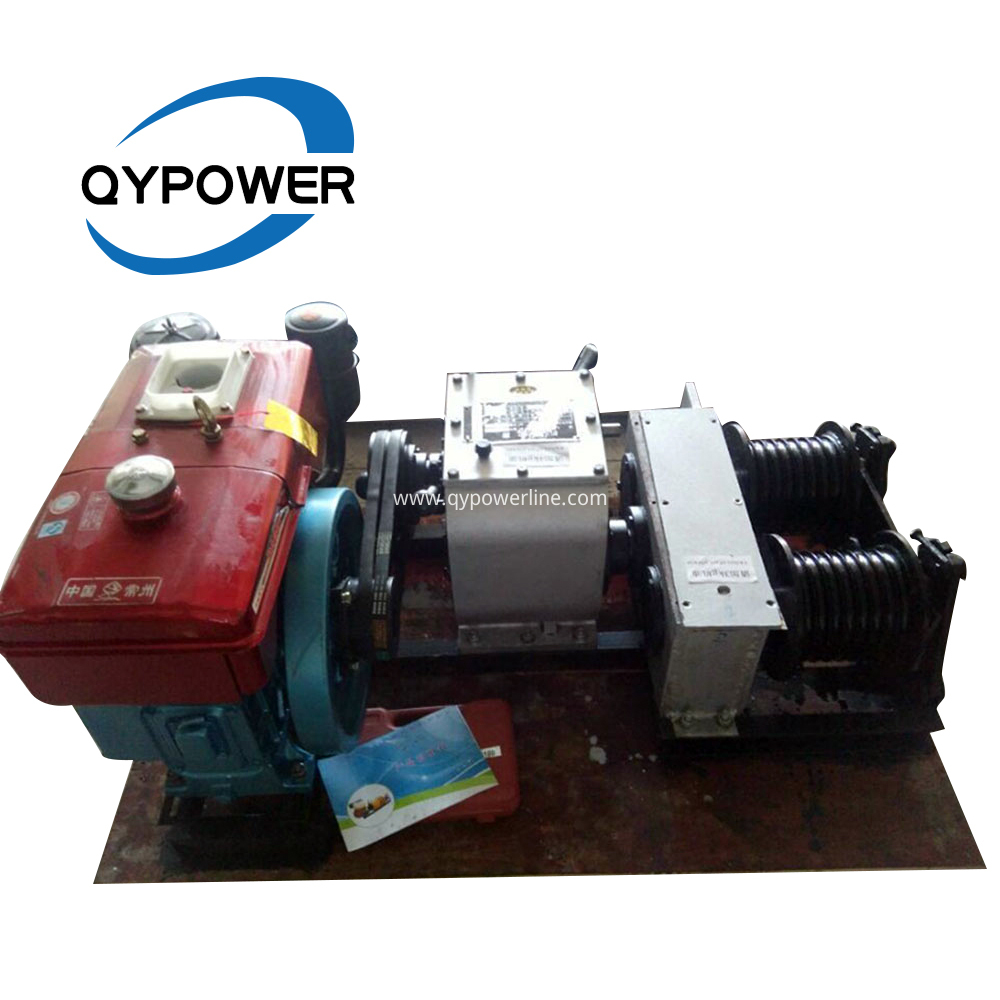

Detailed loading and unloading procedures for Engine Powered Winch, engine-driven winch, petrol-powered winch, portable petrol winch, capstan winch

1 Preparation before work

1.1 clean up 5 meters of sundries and flammable and explosive items. The 1.2 unit must be placed in a stationary place, avoid trenches, holes, or soft soil, and have anti-sliding measures, and the placement position is 1.5 times as high as the height of the tower. 1.3 anchor (pile) installation to comply with the following options: 1) the use of horizontal anchor, anchor set should lead to the direction of excavation and Ma Ma Road, the stress direction should be consistent. No tree or exposed rock should be used as the main force anchor pile such as traction or braking. 2) when using iron piles to make anchors, solid iron piles must be used, and anchor piles shall be no less than 3. No hollow and single iron piles shall be strictly prohibited. The steel rope sleeves connected with iron piles should be more than 3.5, and iron wire instead of steel rope sleeves shall not be used.

1.4 Wire Rope installation methods: 1) the wire rope buckle tower screw loose, open bracket, face grinding core, the traction rope from a clockwise direction around the inlet end near the drum of engine-driven winch, traction bracket, the tail rope near the end of transmission, and the traction rope drum must be vertical. 2) there must be no less than 5 circles on the winding reel of the traction rope and arranged in order, and the safety device must be set at the end of the rope. After the grinding rope is wound, the grinding core lock is closed and the fixed bolt is tightened with the wrench. 1.5, the two anchorage points of the motor milling shall be anchored to the ground anchor when connected by a steel rope. The length of the connecting steel rope must be greater than two times the distance between the connection points, the connection shall be reliable and reliable, and there shall be measures to prevent the string movement.

1.6 the force ring of the maneuver grinder is set up to connect with the ground pile. In use, the connection position can not be decided outside the force ring.

1.7 all lubricating parts are added to the lubricating oil as specified. 1.8 add oil from the upper injection port of the engine fuel tank to the bottom of the filter, and do not overflow. 1.9 from the engine oil tank bottom oil injection into the mouth, the oil level is higher than the upper limit of the oil gauge. 1.10 check whether the engine air filter is blocked. 1.11 the unit shell is grounded and the ground resistance is not more than 4 ohms. 1.12 inspection of the fuel tank cover and the connecting bolts of each part should be intact and no loosening. 1.13 units installed check without exception, should be 4 minutes no-load test, check the clutch, gearbox, brake, reducer and gear pull handle is flexible, accurate and reliable, no jamming phenomenon.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.